Best Practices for UV-Cure Adhesives, 2016-03-01, Assembly Magazine

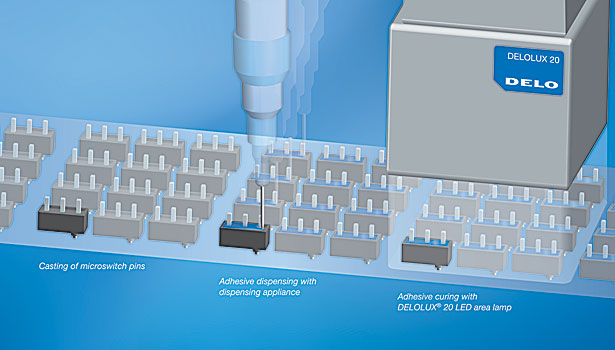

Every assembly application involves multiple steps, but not every step presents the same level of difficulty. Before bonding parts, for example, an assembler will usually have little trouble preparing the dispensing system or fixturing parts. The bigger challenges involve selecting the right adhesive and making sure it is properly dispensed and cured. Ammunition manufacturer Sellier and Bellot is familiar with these challenges, having faced them for many years while using a solvent-based sealant to seal the bullet and primer of various caliber ammunition (0.38, 0.40 . . .

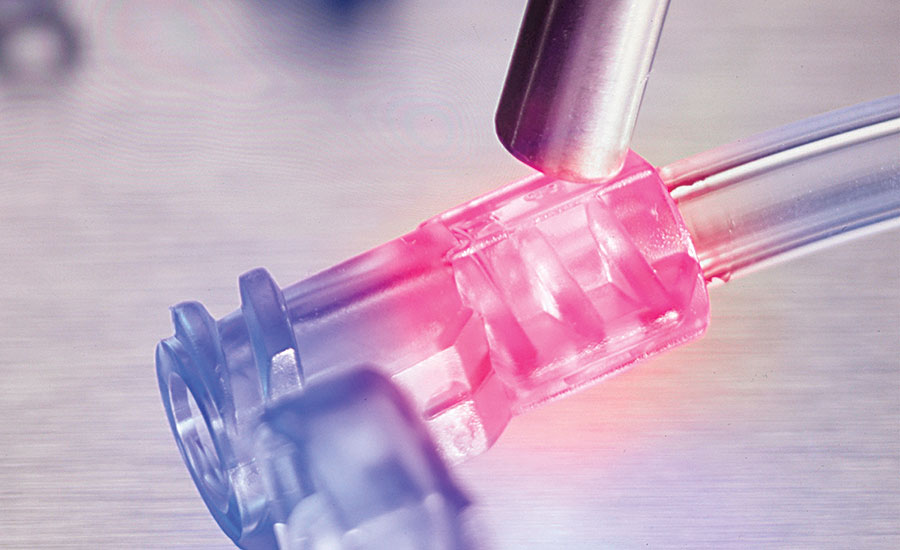

For optimal results when using UV-cure adhesives, engineers should shield the adhesive from light and match the wavelength of light to the adhesive.

Boost Productivity With UV-Curing Adhesives

EP1943965B1 - Apparatus for closing a curved anvil of a surgical

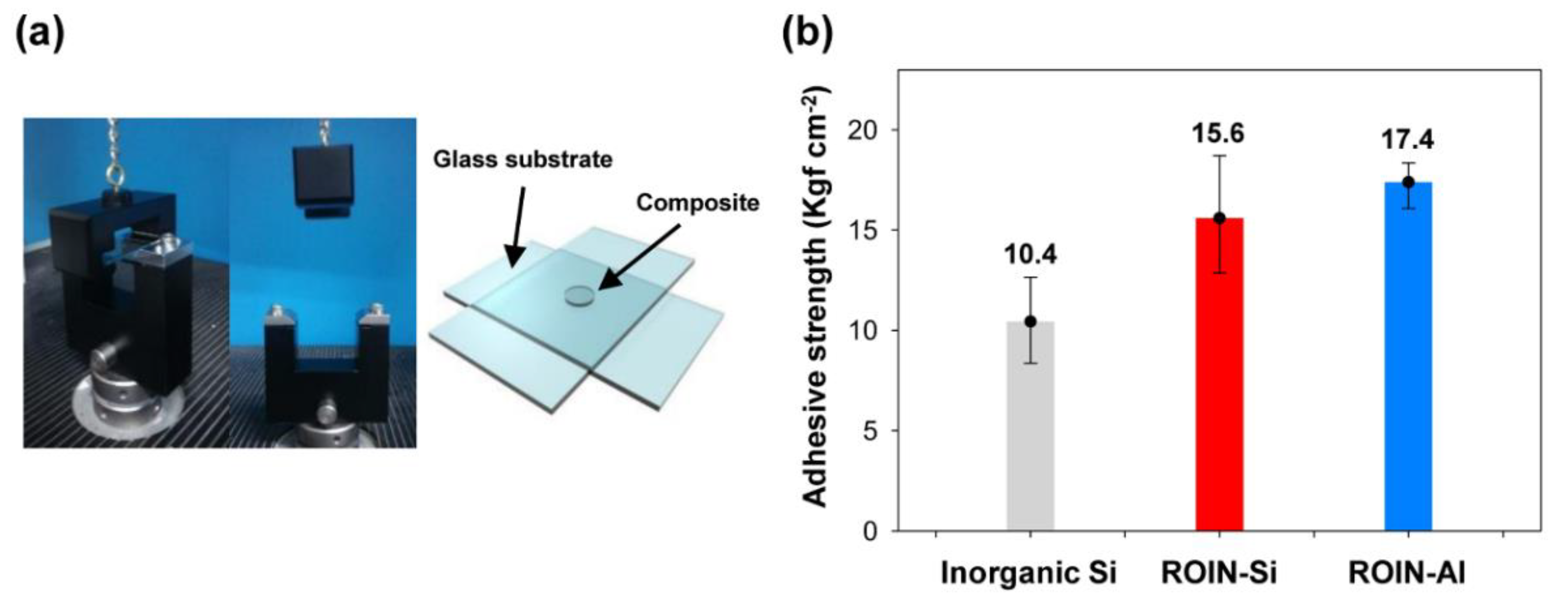

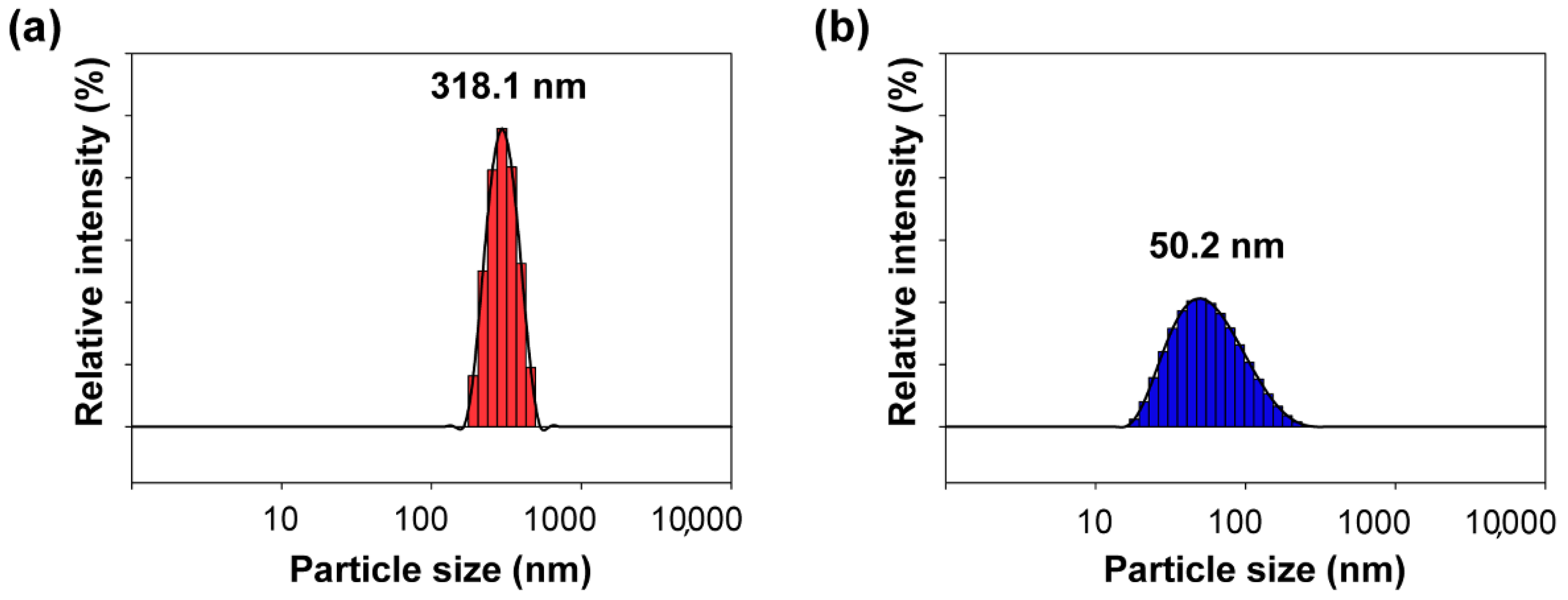

Polymers, Free Full-Text

US10941490B2 - Multiple temperature range susceptor, assembly

GoldMedal 2016 Web, PDF, Popcorn

Addressing Unmet Clinical Needs with UV Bioadhesives

Polymers, Free Full-Text

Boost Productivity With UV-Curing Adhesives

Best Practices for UV-Cure Adhesives, 2016-03-01

US11081345B2 - Method of post-deposition treatment for silicon

Boost Productivity With UV-Curing Adhesives

UV Adhesive - More than the name implies - PROSTECH

Is my UV curable adhesive cured?

US20140243865A1 - Interchangeable tools for surgical instruments

Loctite 3103 Flexible Light Cure Adhesive - Part # 23691 - 25mL