Colored Resin Addition Process In Molded Plastics, Part 2

For many applications, color additives in plastic injection molding are vital factors. Here are some basics on color matching and impact on characteristics.

True Translucent is a translucent 2 part liquid polyurethane product that cures out to a translucent semi rigid plastic feel. Mix ratio is 1:1 parts

2 Part Polyurethane Casting Resin - Easy to Tint and Pigment - 3 Minute Gel time - ~15 Minute demold time - Semi Rigid Plastic Feel - 70 Shore D

Top 5 Biodegradable Resins For Your Plastic Injection Molding Project

A compression molding epoxy system for fast cycle times in heat-assisted molding processes of fiber-reinforced composites. Make Things Better® on your

Compression Molding Epoxy

The Importance of Gauging Residence-Time Distribution—Part 2

The Complete Guide to DIY Molding & Resin Casting

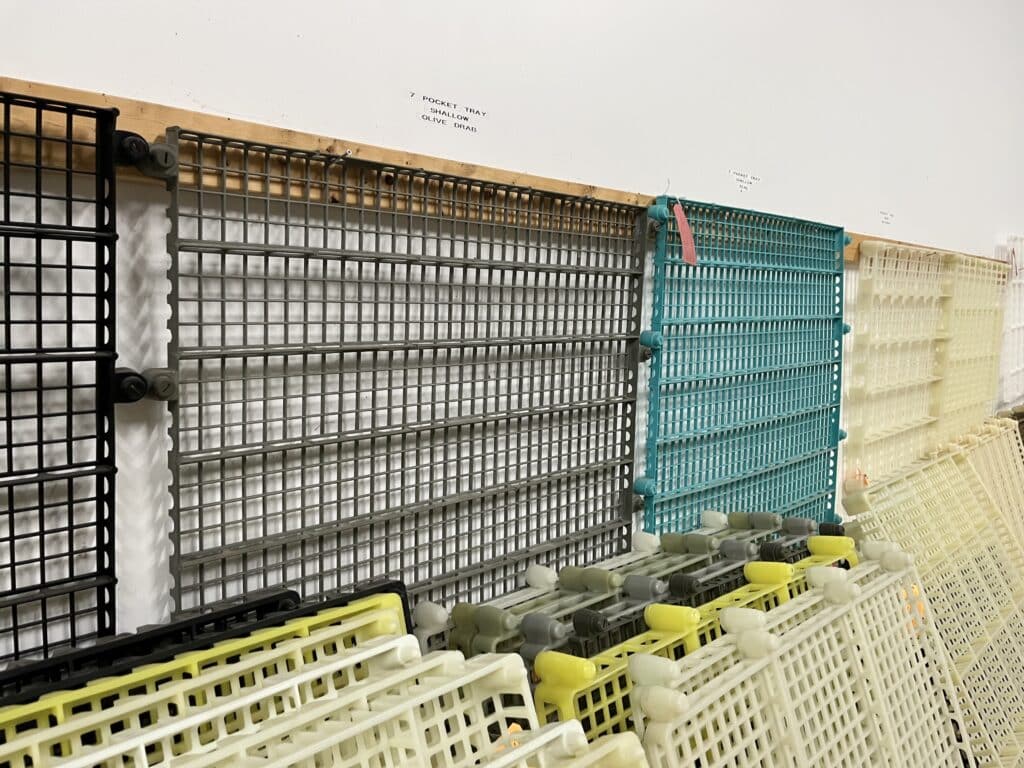

5 Common Plastic Resins Used in Injection Molding

Two-Shot Injection Molding Services

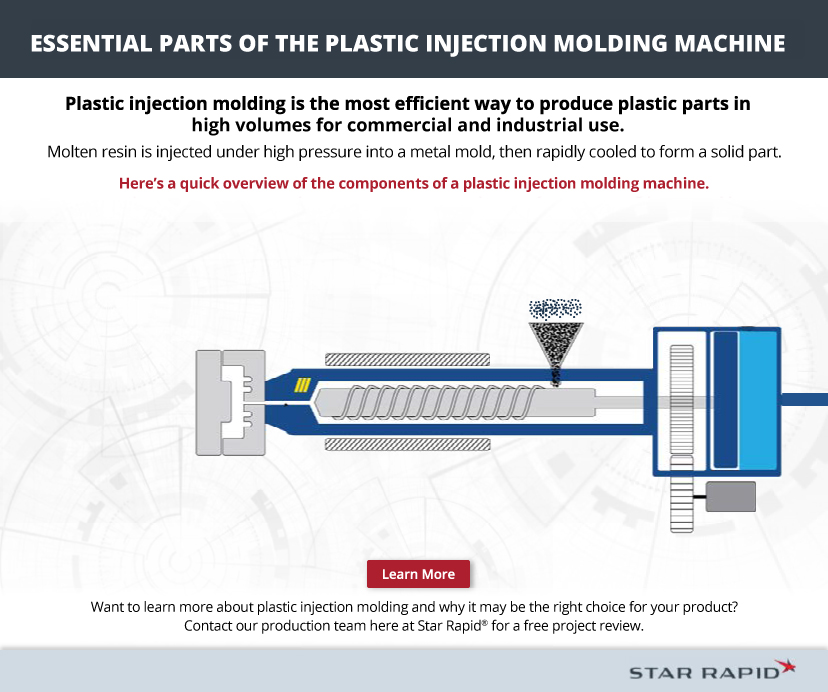

Basics of Injection Molding Design

*5 Colors Chrome Mica Pigment Powder: 5 different colors high-quality color changing epoxy resin pigment, each 0.5g. You'll need just a little to

LET'S RESIN Chameleon Flakes, Resin Supplies -Intense Color Shift Pigment Powder for Resin Molds/Tumblers, Chrome Powder Pigment for Christmas Nail

Plastic Injection Molding Services

True Translucent is a translucent 2 part liquid polyurethane product that cures out to a translucent semi rigid plastic feel. Mix ratio is 1:1 parts

2 Part Polyurethane Casting Resin - Easy to Tint and Pigment - 3 Minute Gel time - ~15 Minute demold time - Semi Rigid Plastic Feel - 70 Shore D

10 Methods for Coloring Plastics